Researchers Find A Way To 3D Print Using Glass Instead Of Plastic

While plastic has been the go-to for 3D printing so far, researches at the Massachusetts Institute of Technology (MIT) have found a way to 3D print using glass. The result, says the MIT team led by Neri Oxman and Peter Houk, is a machine that produces the first of its kind optically transparent 3D-printed glass.

Blending ancient Egyptian manufacturing techniques with the latest in 3D printing technology, there is now a way to “print” 3D objects made entirely from glass. The varying thickness of the printed object can allow for creations that control light transmission, reflection and refraction according to MIT researchers. Essentially fiber optics could be integrated into the glass façade of a building.

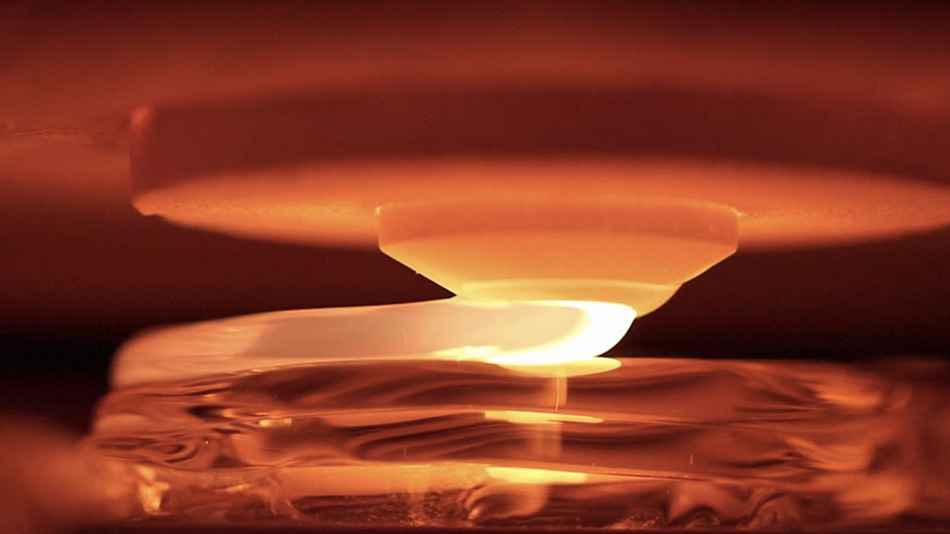

While it looks great in the video above, how exactly does the G3DP platform work? The lower chamber, meanwhile, functions to anneal the 3D printed structures. Drawing from a chamber of molten glass heated to 1,000°C, the printer uses an alumina-zircon-silica nozzle to drizzle small layers to slowly build the glassware. Together, the two chambers are able to manufacture a wide number of shapes in a relatively quick fashion.

3D printing has come a long way in the last few years with printers getting cheaper and printing materials becoming easier to work with. Shapes can be designed on the computer, and the G3DP will execute them. “Glass can be distributed in a more sophisticated way throughout the cross section of each component, and intricate inner features are feasible which enable the incorporation of internal channels to distribute water, air and other biological mediums”.