MIT Creates a 3D Printer for Glass

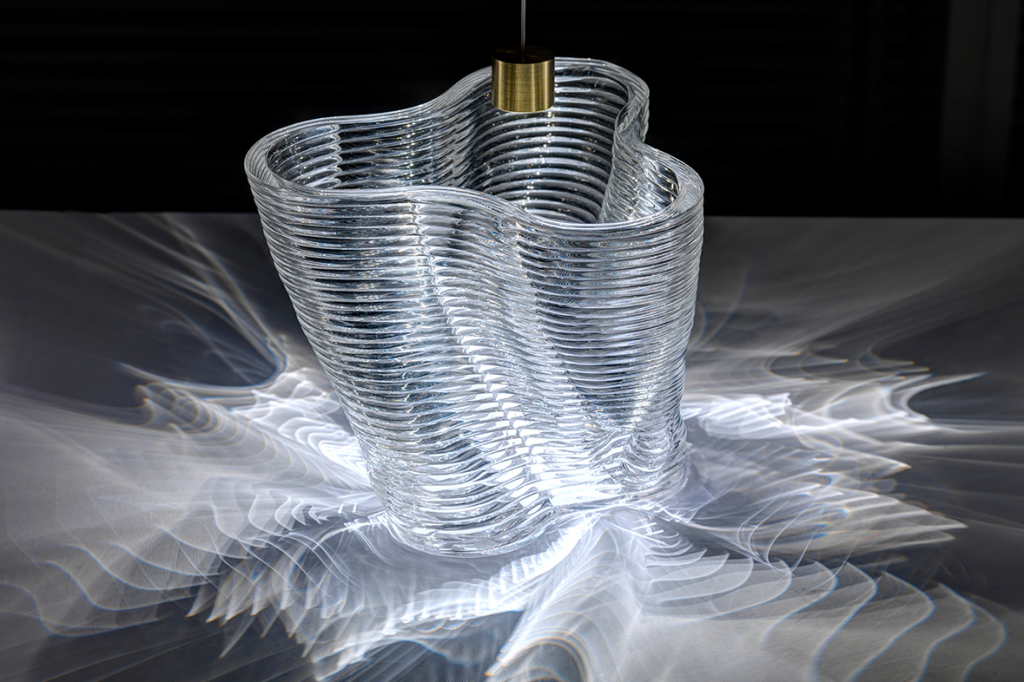

Describing it as “a first of its kind optically transparent glass printing process”, the Mediated Matter Group at MIT’s Glass Lab developed G3DP -Glass 3D Printing.

The molten glass and “printer” can be adjusted to change how the final product looks.

Here’s how it works.

Blending ancient Egyptian manufacturing techniques with the latest in 3D printing technology, there is now a way to “print” 3D objects made entirely from glass.

To explain, Mediated Matter is a group founded by Neri Oxman, the Sony Corporation Career Development Professor and Associate Professor of Media Arts and Sciences at the MIT Media Lab.

The lower chamber works to anneal the material, and the end result is a rather funky shaped glass. “The Kiln Cartridge operates at approximately 1,900°F and can contain sufficient material to build a single architectural component”.

The printer’s nozzle, by the way, is alumina-zircon-silica, which is then cooled with an air compressor when they want to snap off the printing process.

MIT researchers are confident their new technology will have many potential applications going forward. “The tunability enabled by geometrical and optical variation driven by form, transparency and color variation can drive; limit or control light transmission, reflection and refraction, and therefore carries significant implications for all things glass: aerodynamic building facades optimized for solar gain, geometrically customized and variable thickness lighting devices and so on”. A selection of the objects produced will appear in an exhibition at the Smithsonian Design Museum in New York in 2016.