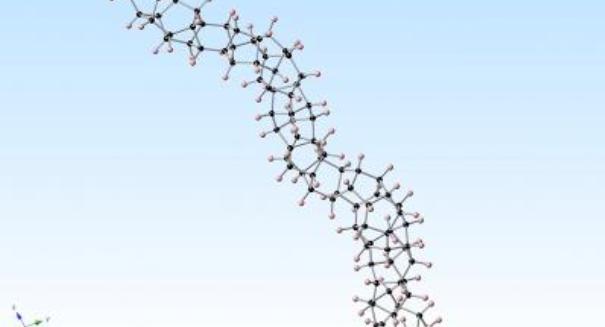

Creating carbon nanofibres from carbon dioxide in the air

Thus, the nanofibers are created out of carbon and the lithium oxide produced can be used for further reactions. Finding a technology to shift carbon dioxide (CO2), the most abundant anthropogenic greenhouse gas, from a climate change problem to a valuable commodity has always been a dream of many scientists and government officials.

Prof. Licht and his team of researchers need to work on improving this part of their technique, before it could be used as a viable and cost-effective solution of obtaining the carbon nanofibers. Already, the substance is used in the Boeing 787 Dreamliner, high-end sports equipment and wind turbine blades, among other products, according to Licht.

The upshot of the process is, according to Licht, if he was able to scale his project to a size that would cover less than 10 percent of the Sahara Desert, it could draw enough Carbon dioxide out of the atmosphere to concentrations down to pre-industrial levels within just 10 years.

One of the biggest threats facing humanity is climate change, and reducing the amount of Carbon dioxide that we’re pumping into the atmosphere is the only way to mitigate its effects.

The future potential uses for carbon nanofibers are almost limitless, and include use in tougher bulletproof vests, artificial muscles or rebuilding damaged hearts.

A chemical engineer and clean energy researcher at Imperial College London named Dr. Paul Fennell said that “if they can make carbon nanofibers, that is a laudable aim and they’re a worthwhile product to have”.

The research is being presented at the 250th National Meeting & Exposition of the American Chemical Society in Boston this week.

The researchers are using an extremely efficient hybrid concentrating solar-energy system that combines an electricity generating photovoltaic solar cell and a heat and thermal energy generator.

The cost of doing this is an astonishingly cheap $1,000 per ton of carbon nanofibers. Scientists believe that it’s possible: a new process developed by team at George Washington University could manufacture the fibers using carbon dioxide extracted from Earth’s atmosphere – talk about a win/win for everyone. CO2 is broken down in a high-temperature electrolytic bath of molten carbonates at 750°C. On a secondary system, the sunlight is focused to generate heat and thermal energy, in order to raise the temperature of the electrolytic cell. The system now generates 10g of nanofibers in a single hour. “Right now, there just isn’t a market for the stuff; no surprise, given that it costs 30 to 100 times more to make than aluminum”, Gizmodo wrote.

The technology is still in the experimental stage, but the research team said they are scaling up quickly. The question is whether the process can make consistently sized nanofibers.