FI BREAKTHROUGH Ultrathin ‘invisibility cloak’ can match any background

Scientists said on Thursday they’ve safely and effectively studied an ultra-thin invisibility cloak constructed from small square good streets which typically, like dermis, comply with the form pertaining to an thing and may supply it hidden by having light.

If the cloak, which is now on the microscopic level, were big enough, “You could cover a tank with it and make it look like a bicycle”, said Zhang.

The researchers say that it isn’t hard to make the reflected like anything you want, either the background of the object (like Harry Potter’s cloak) or another object.

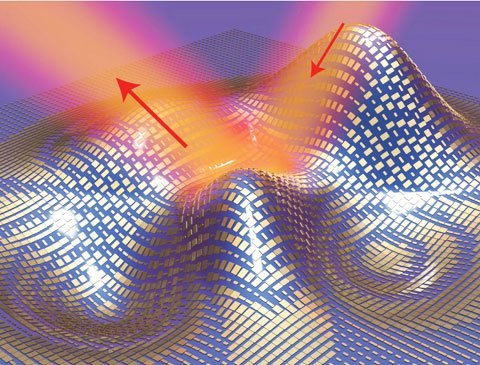

When a cloaked object is illuminated by 730-nanometer wavelength (deep red) light, the antennas make the cloak act like a perfectly flat mirror, regardless of its current shape.

“As long as the metasurface is designed correctly… both the container and the objects inside the container will become invisible“, the study claims. Invisibility skin cloaks on the microscopic scale might prove valuable for hiding the detailed layout of microelectronic components or for security encryption purposes.

What makes this experiment utterly unique is that the invisibility cloak does not change in shape regardless of the thickness or size of the concealed object. They can counteract that distortion, making it seem like the light is coming from a flat surface.

Usually, when light bounces off an object, it is scattered and the wavefront gets distorted – what lets us see the object’s angles and curves.

Made up of millions of small reflective gold nano-antennas, this fantastic new material prevents light from scattering off an object and distorts it, the process through which something is made visible. The paper is titled “An Ultra-Thin Invisibility Skin Cloak for Visible Light”.

The technology used in developing the invisible cloak has been around for more than a decade. The cloak can be turned “on” or “off” simply by switching the polarization of the nanoantennas.

“One application might be in cosmetics”, said Zhang.

This research was funded by the DOE Office of Science.

It may take five to 10 years to make the technology practical to use, according to Xiang Zhang, director of the Materials Sciences Division of the U.S. Department of Energy’s Lawrence Berkeley National Laboratory and a professor at the University of California, Berkeley. Founded in 1931, Berkeley Lab’s scientific expertise has been recognized with 13 Nobel prizes. For more, visit www.lbl.gov.