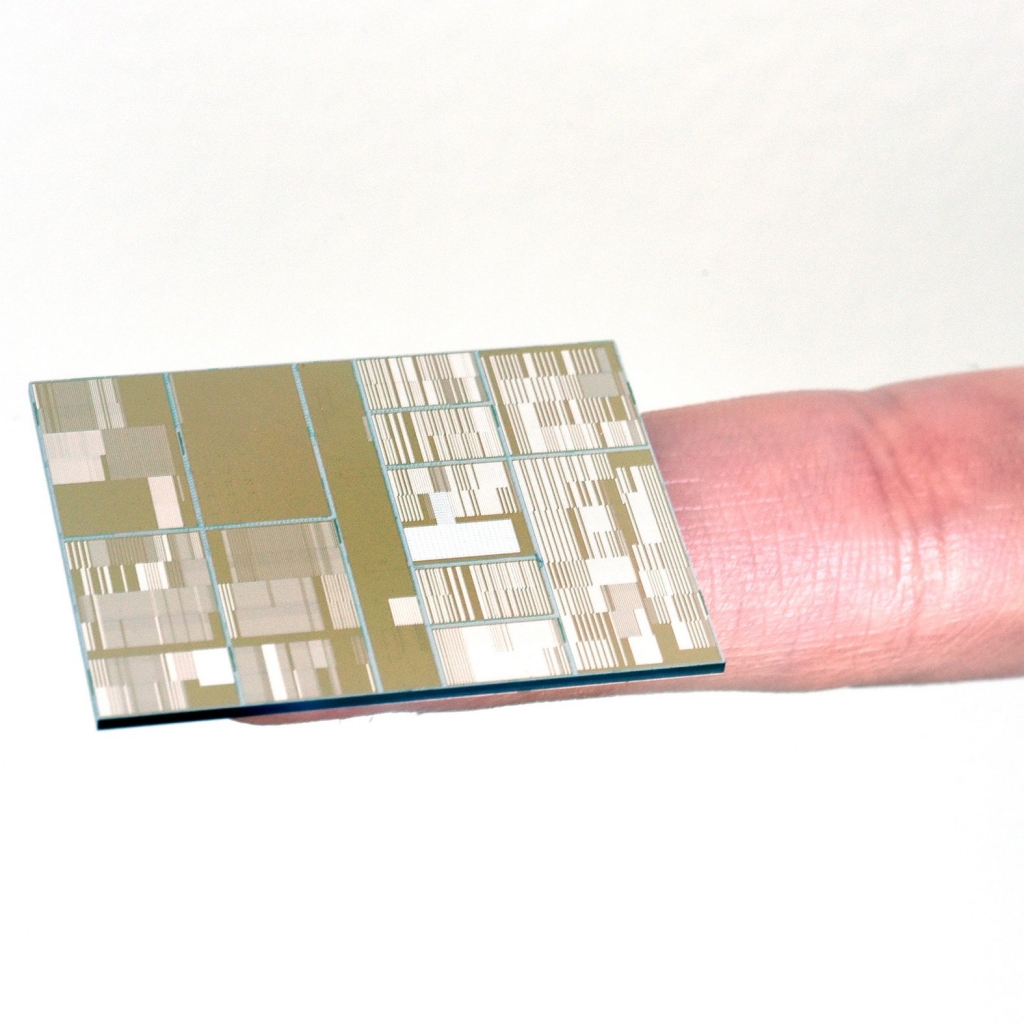

IBM Research builds functional 7nm processor

In addition, IBM Research pointed to ten previous breakthroughs in the world of chippery that led to the 7nm process (see diagram right). For some context, a strand of DNA measures 2.5 nanometers in diameter.

We do know that it is Intel that usually gets crowned for being the forerunners in this field but if and when IBM gets to launch the 7 nanometer chip in the market it would definitely be a game changer for both companies – for better or worse.

To create its 7mn test chips with functional transistors, IBM made “fundamental changes” in the materials used to create the chip as well as adopting new lithography techniques, said Mukesh Khare, vice president of semiconductor technology for IBM Research, in an interview. However, the IBM test chips are experimental devices not ready for commercial exploitation.

The company had last year pledged US$3-billion to fund its micro-processing development, and it seems that it’s putting it to good use.

These new micro-sized transistors mean that IBM and its partners will be able to produce microprocessors containing 20 billion transistors, boosting processor power and energy efficiency significantly. He expected this trend – which meant that computer power effectively doubled every two years – to continue.

What’s more impressive is that the 7nm process was only penciled in my chip manufacturer, TSMC, for 2017, so the technology itself is at least two years away from becoming a primary part of consumer computing. Previous attempts to make a 7nm chip haven’t been efficient enough and have needed too much power to run, the New York Times points out.

Specific IBM contributions to the project include the invention or first implementation of a single-cell DRAM, the Dennard Scaling Laws, chemically amplified photoresists, copper interconnect wiring, Silicon on Insulator, strained engineering, multicore microprocessors, immersion lithography, high-speed SiGe, High-k gate dielectrics, embedded DRAM, 3D chip stacking, and Air gap insulators.

The new technology uses extreme ultraviolet light to etch the chips, which requires “specialized stabilized buildings” to ensure the equipment does not vibrate during the process.